Product features

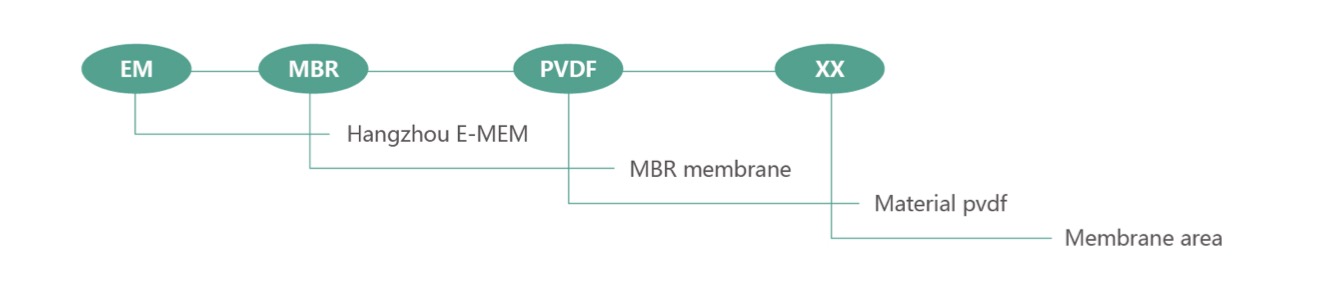

Zhejiang E-MEM curtain-type MBR membrane is produced by own patent composite spinning technology. On the surface of the textile tube, it is the high-performance separating layer of PVDF. By optimizing the formula of separating layer and the craft of surface pretreatment, it makes the hollow fiber of MBR featured with super-high tensile strength and high separation accuracy.

E-MEM MBR application:

Ø Drinking water treatment, the removal rate of ultrafiltration membrane can reach 61og for bacteria and 41og for viruses, so water plants and water users do not need to worry about bacteria and viruses, in same time the recovery rate can be 99%

Ø Surface water treatment,used for irrigation or as water for reverse osmosis to prepare purified water.

Ø Seawater treatment pretreatment, MBR system can control the water quality of seawater very confidently, provide high quality water entry for reverse osmosis system, and ensure the stable operation of reverse osmosis system.

Ø Wastewater recycling to meet industrial reclaimed water usage.