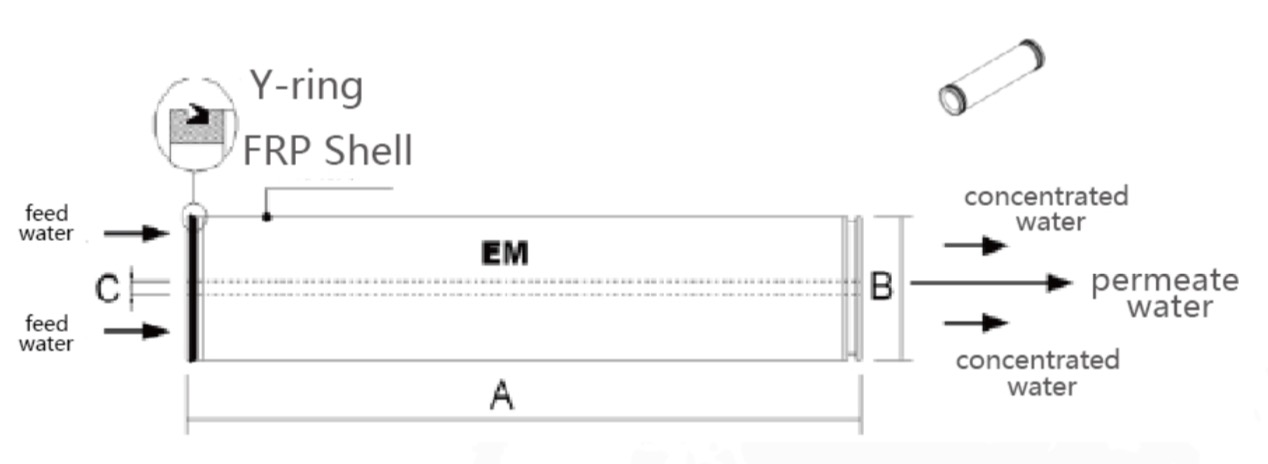

Product introduction

E-MEM industrial NF membrane element is mainly used to remove organic matter, microorganism, virus and most divalent and above metal ions in water, and retain some sodium (Na) and potassium(K) plasma. Nanofiltration membrane separation process does not have any chemical reaction, no phase transformation, no heating, will not destroy the biological activity, widely used in drinking water devices, sewage treatment and food, medicine, biological engineering and other industries in the liquid separation and concentration purification process.