Product introduction

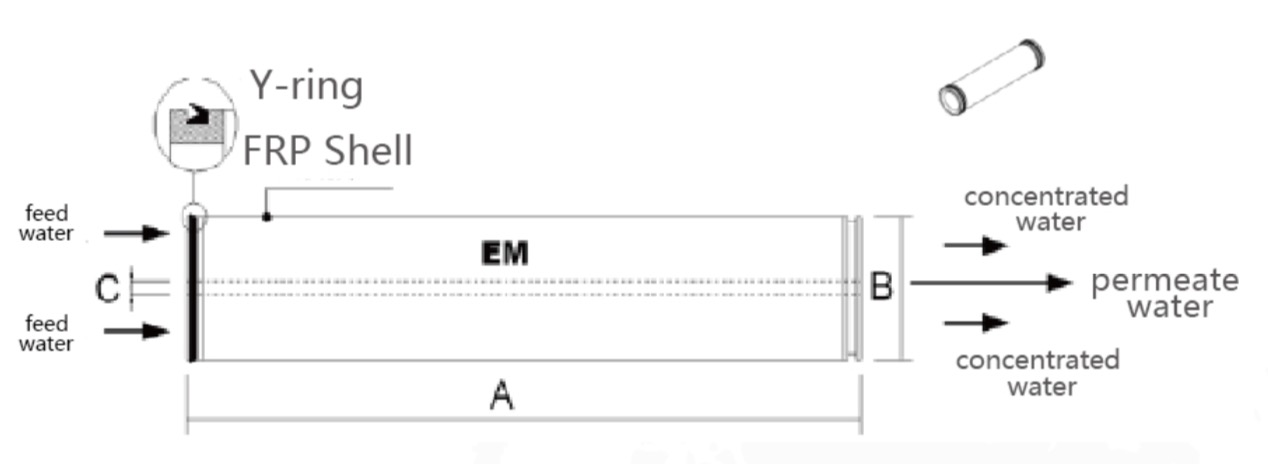

FR (Fouling Resistant) series membrane is aromatic polyamide composite membrane element which is used in brackish water desalination, research and development from Hangzhou E-MEM Environmental Technology Co., Ltd. FR series membrane with its features of low operation pressure, high water flow, and high desalination rate. The unique anti-pollution patented technology is adopted to modify the membrane surface to change the charge and smoothness of the membrane surface, increase the hydrophilicity of the membrane surface, reduce the adhesion of pollutants and microorganisms on the membrane surface, reduce the pollution rate of membrane components, and extend the service life; At the same time, 34mil feed spacer design is adopted to reduce pressure loss and improve cleaning recovery. FR series are suitable for desalination of surface water, municipal water and industrial wastewater with a salt content of less than 8000ppm. They are mainly used for reuse of reclaimed water, boiler make-up water, circulating cooling water and other water treatment fields of various sizes. They are especially suitable for polluted water sources containing a small amount of organic matter.