Features:

Ø High water flow,

Ø super recovery, can reach 99% in drinking water

Ø lower investment

Ø The pretreatment process is simple

Ø Small floor area and low operating cost

Ø good water quality and high biological safety, the effluent turbidity is close to zero (≤0.1NTU)

The main features of the open-type submerged ultrafiltration membrane are as follows:

(1) simple pretreatment process: generally, coagulation precipitation and multi-medium filtration are not required, and high concentration suspended solids can be directly filtered without complex pretreatment (such as up to 200NTU). For example, MBR is a special application of submerged ultrafiltration membrane, which directly filters the suspended sludge up to 10000mg/L.

(2) Good water quality and high biosafety: the turbidity of the effluent is close to zero (≤0.1NTU), which can remove bacteria, viruses and E. coli. The removal rate of "two worms" in the deep treatment of drinking water is more than 6log;

(3) No disinfection by-products: it has a physical disinfection function in the removal of microorganisms, which can replace the disinfection of agents to avoid the generation of disinfection by-products;

(4) Small floor area and low operating cost: low negative pressure water production by pumping or siphoning, low transmembrane differential pressure and high flux filtration, low energy consumption for water production, and greater water production in the same area;

(5) Convenient operation management: high degree of automation, automatic control can be realized, convenient management;

(6) Convenience of secondary reconstruction: integrated module, especially suitable for large-scale reclaimed water projects and filter tank upgrading in water treatment plants.

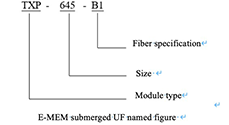

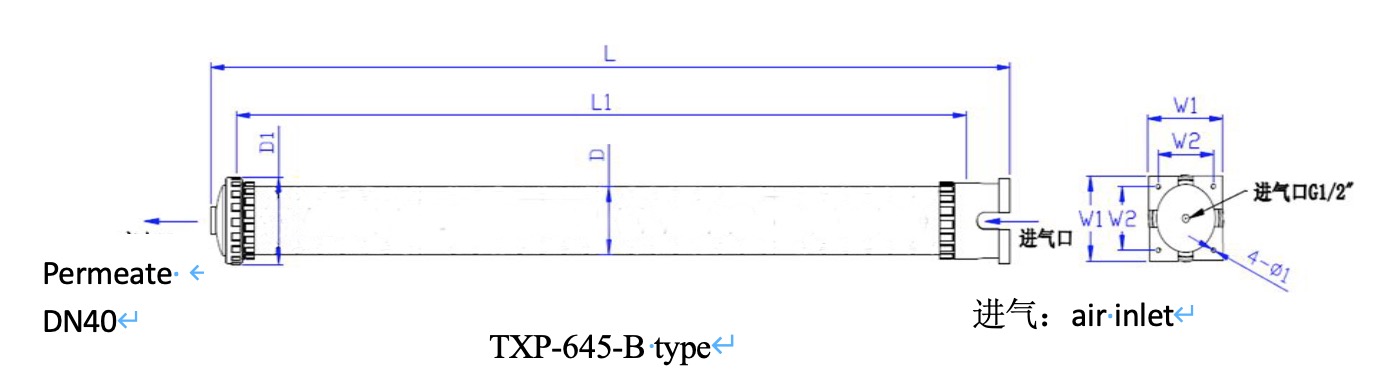

The diameter of the membrane element in inches (value ×0.1) and the membrane area in square meters are expressed as:

TXP:submerged type

645:diamter 6 inch and membrane area 45sqm

B1:Model of submerged UF membrane module and membrane fibers:

A-first generation,B-second genegeration;Numbers-fiber outer diameter and fiber type,without numbers-OD1.3mm, 1-OD1.6mm,2-OD 2.0mm

|

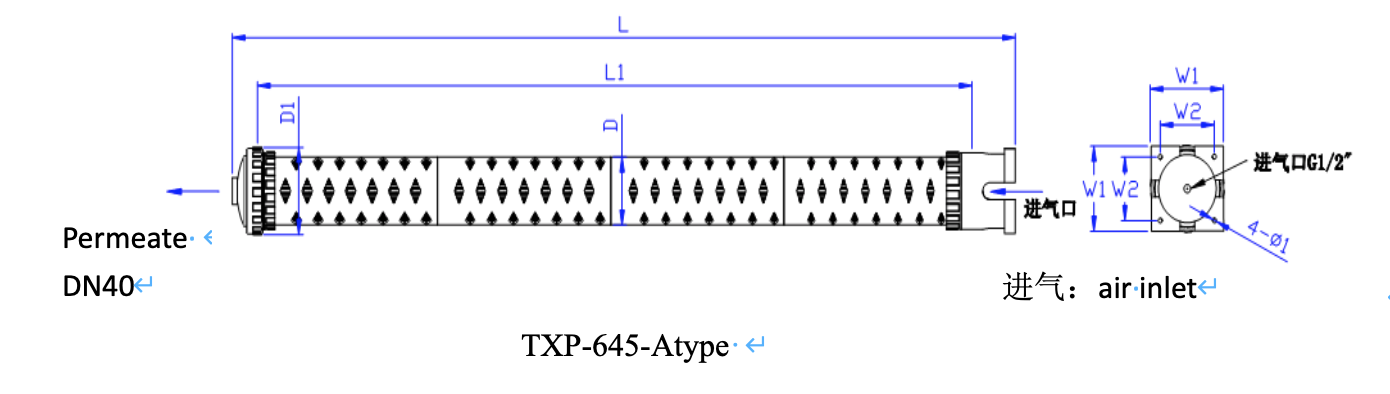

Mode |

L |

L1 |

D |

D1 |

W1 |

W2 |

φ1 |

Unit |

|

TXP-645-A |

2168±5 |

1987±3 |

160 |

205 |

200 |

150 |

12.5 |

mm |

|

Model |

L |

L1 |

D1 |

φ1 |

W1 |

W2 |

Unit |

|

TXP-645-B1

TXP-645-B2 |

2168±5 |

1987±3 |

205±2 |

12.5±0.2 |

200±1 |

150±1 |

mm |

|

Item |

description |

||

|

Model |

TXP-645-A |

TXP-645-B1 |

TXP-645-B2 |

|

Filtration membrane |

|||

|

Material |

PVDF |

||

|

Fiber Qty |

5800 |

4720 |

3780 |

|

Active membrane area(m2) |

45 |

||

|

Fiber performance |

|||

|

ID/OD(mm) |

0.7/1.3 |

0.7/1.4 |

1.1/2.0 |

|

Pore size(μm) |

0.03 |

0.02 |

0.02 |

|

Tensile strength(N) |

≥5 |

≥110 |

≥150 |

|

Using condition |

|||

|

Suction filtration Max pressure(kPa) |

-80 |

||

|

Maximum pressure difference between inside and outside the membrane(kPa) |

150 |

||

|

Temperature(℃) |

5-45 |

||

|

pH range |

2—11 |

||

|

Recommend pH |

6—9 |

||

|

Using component materials |

|||

|

Top & bottom |

UPVC |

||

|

Binder |

Epoxy resin |

||

|

Gasket |

EPDM |

||

|

Module size(mm) |

φ160×2168L |

||

|

Dry weight(kg) |

15 |

18 |

20 |

|

Wet weight(after water discharge)(kg) |

25 |

28 |

30 |

|

Protection liquid |

Glycerol aqueous solution |

||